Rigid Foam Insulation Under Concrete Slab

Rigid Foam Insulation Under Concrete Slab. A second solution would have been placing the slab and then building a sleeper system on top of it to support the floor. Types of insulation for under concrete slab.

The Dirt on BelowGrade Insulation Insulfoam from www.insulfoam.com

The Dirt on BelowGrade Insulation Insulfoam from www.insulfoam.comThe problem is that designers often do not adequately account for. Say you use an average (and relatively inexpensive) rating of 40 psi, then the insulation will support: 40 psi x 8" wide tire x 12" long tire print = 3,840 lbs.

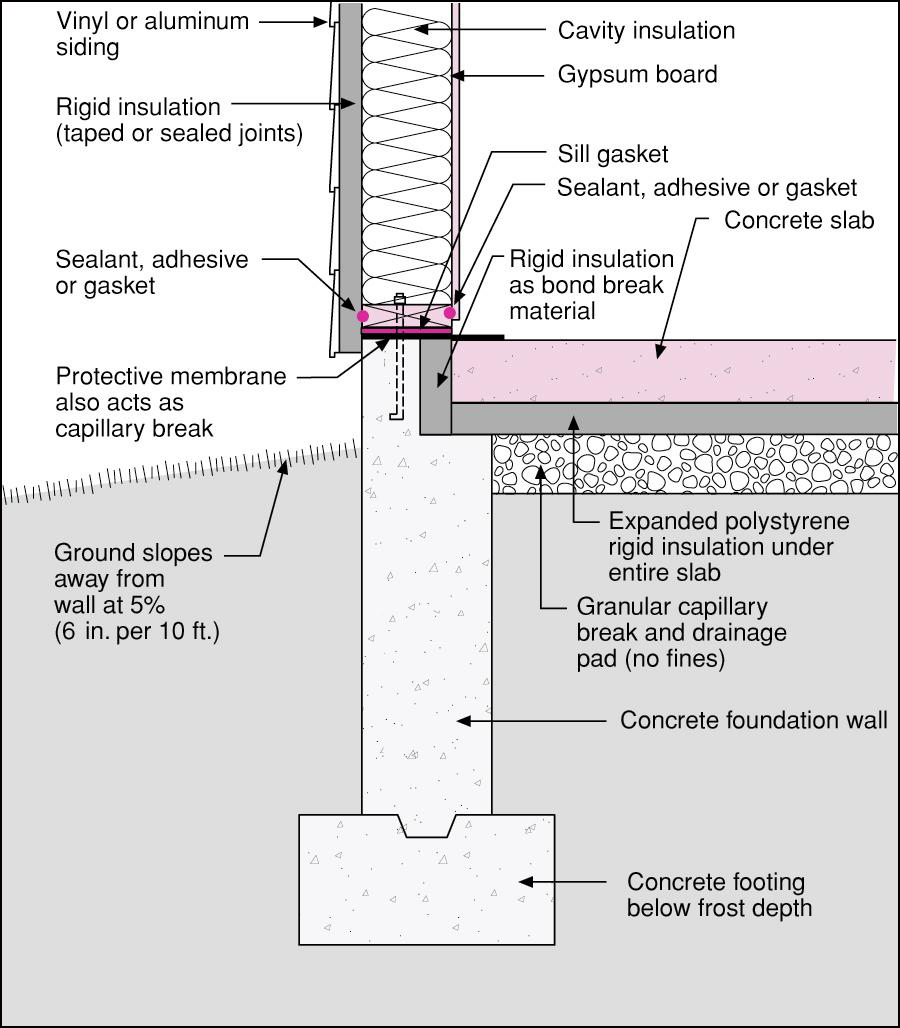

Rigid foam under a concrete slab is a complex but important topic to dig into, especially when building codes come into play. One solution would have been installing rigid insulation under the slab, turning it up on the perimeter (to form a giant pan), and then casting the concrete slab inside the pan.

The problem is that designers often do not adequately account for. More about ecofoil under concrete slab insulation.

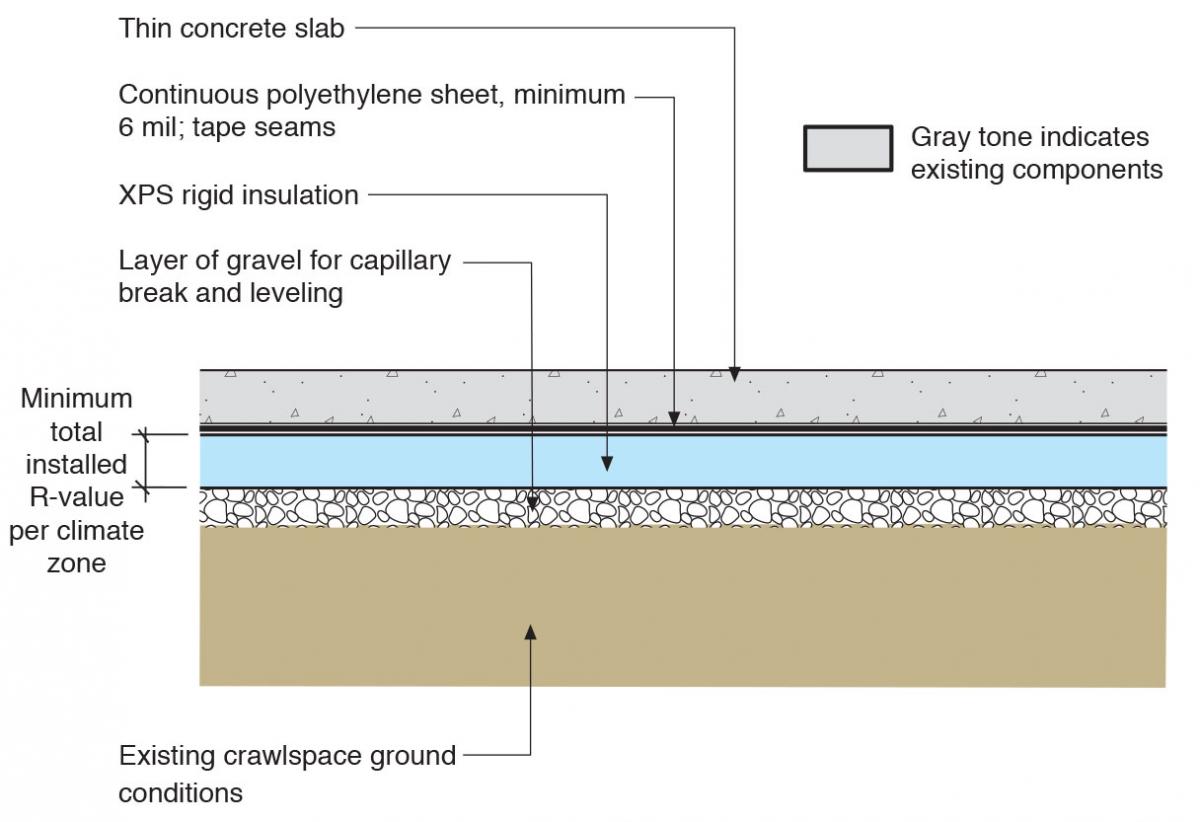

Rigid insulation concrete products like foam sheeting are easily broken and must be used with an extra vapor barrier, plus standard foam or polystyrene concrete insulation does not stop radiant heat. One solution would have been installing rigid insulation under the slab, turning it up on the perimeter (to form a giant pan), and then casting the concrete slab inside the pan.

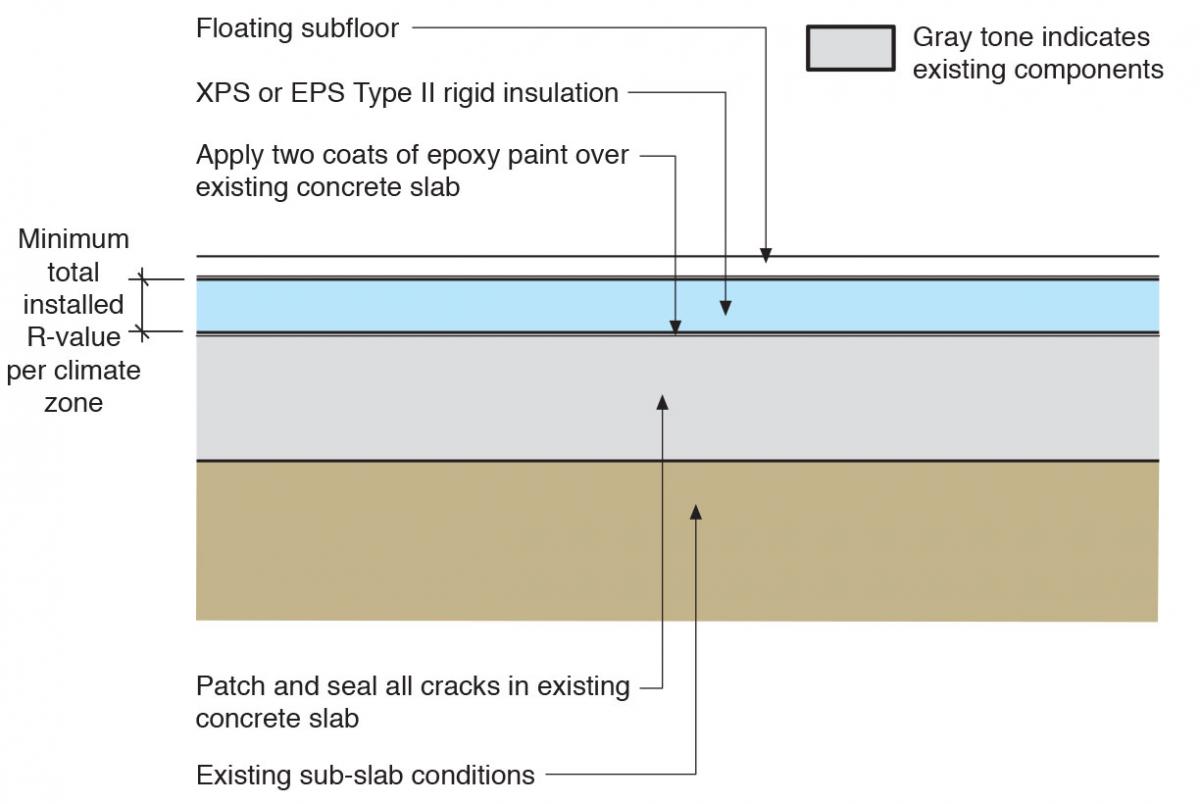

Finally, some contractors in cold climates began installing a continuous horizontal layer of rigid foam insulation under their concrete slabs. The commonly used rigid foam insulations below concrete slabs are the expanded polystyrene (eps) and extruded polystyrene (xps).

40 psi x 8" wide tire x 12" long tire print = 3,840 lbs. Horizontal insulation placed less than 12 inches below the ground surface or that portion of horizontal insulation extending outward more than 24 inches from the foundation edge should be protected against damage by use of a concrete slab or asphalt paving on the ground surface directly above the insulation or by cementitious board, plywood.

From the building science web site:a sheet polyethylene vapor barrier should be located over the rigid insulation and in direct contact with the concrete slab. One solution would have been installing rigid insulation under the slab, turning it up on the perimeter (to form a giant pan), and then casting the concrete slab inside the pan.

Contains 98% trapped air and. Rigid insulation concrete products like foam sheeting are easily broken and must be used with an extra vapor barrier, plus standard foam or polystyrene concrete insulation does not stop radiant heat.

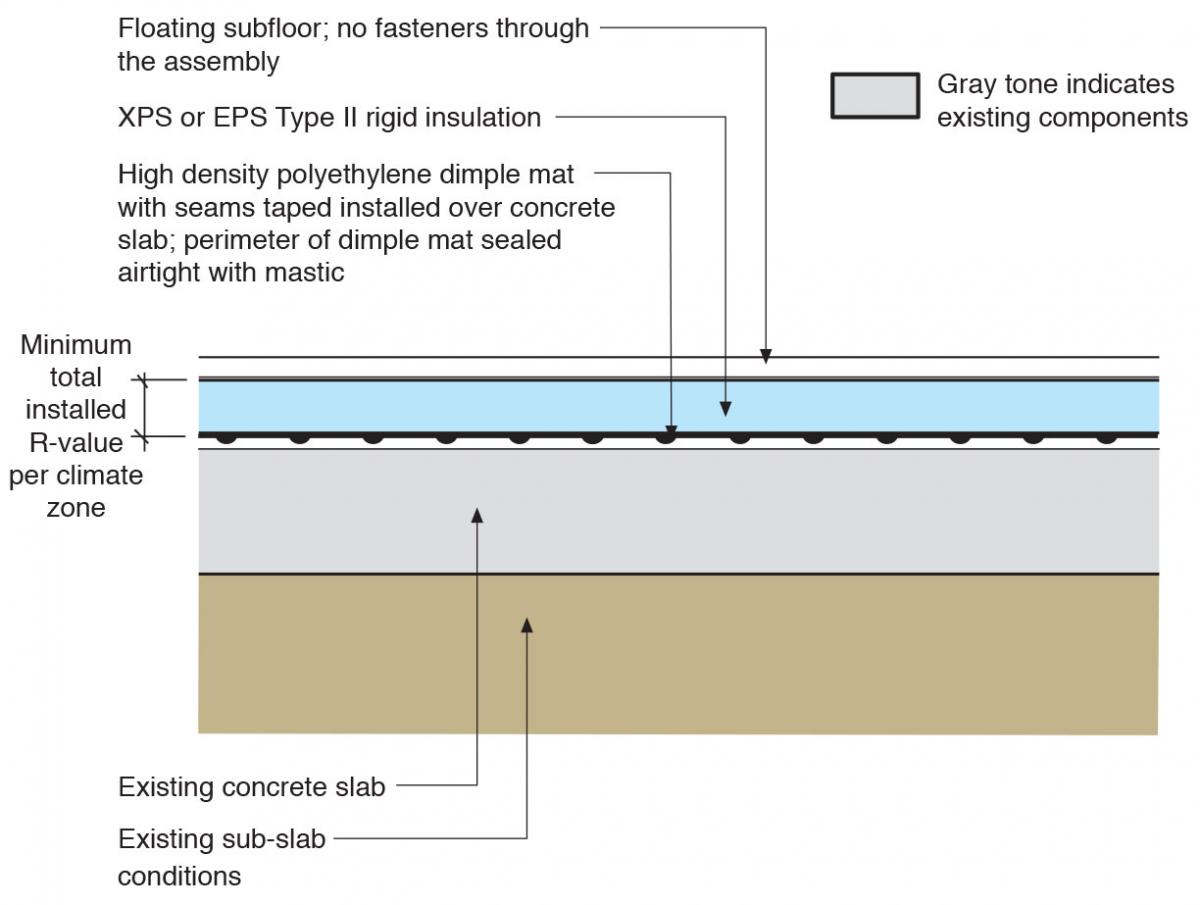

The most common types of under slab or concrete insulation include rigid foam insulations, such as expanded polystyrene (eps), extruded polystyrene (xps) and radiant insulation, such as prodex. Control joints one practice we do, which is needed on all slabs regardless of whether or not, or how, they are insulated, is to cut control joints in the slab to relieve any stress cracking or hairline cracks in.

The most common types of under slab or concrete insulation include rigid foam insulations, such as expanded polystyrene (eps), extruded polystyrene (xps) and radiant insulation, such as prodex. Contains 98% trapped air and.

Using foam insulation under a slab drastically lowers your energy bill, complies with modern codes, and protects the life of the slab. A second solution would have been placing the slab and then building a sleeper system on top of it to support the floor.

Getting the sandwich layers in the right order The commonly used rigid foam insulations below concrete slabs are the expanded polystyrene (eps) and extruded polystyrene (xps).

Control joints one practice we do, which is needed on all slabs regardless of whether or not, or how, they are insulated, is to cut control joints in the slab to relieve any stress cracking or hairline cracks in. Horizontal insulation placed less than 12 inches below the ground surface or that portion of horizontal insulation extending outward more than 24 inches from the foundation edge should be protected against damage by use of a concrete slab or asphalt paving on the ground surface directly above the insulation or by cementitious board, plywood.

A sand layer should never be installed between the sheet polyethylene vapor barrier and the concrete slab. Horizontal insulation placed less than 12 inches below the ground surface or that portion of horizontal insulation extending outward more than 24 inches from the foundation edge should be protected against damage by use of a concrete slab or asphalt paving on the ground surface directly above the insulation or by cementitious board, plywood.

Rigid foam under a concrete slab is a complex but important topic to dig into, especially when building codes come into play. Rigid foam insulations, such as expanded polystyrene (eps), have been used successfully under concrete slabs for more than 40 years.

These people assume that point loads applied to a slab distribute to the insulation in a triangular load path, but in actuality, concrete slabs load more uniformly. Putting the polyethylene above the foam minimizes the risk of iceberging, where if concrete gets under a corner of the foam during the pour it floats up, creating a thin spot in the concrete or even sticking out of the top surface.

Say you use an average (and relatively inexpensive) rating of 40 psi, then the insulation will support: A second solution would have been placing the slab and then building a sleeper system on top of it to support the floor.

A second solution would have been placing the slab and then building a sleeper system on top of it to support the floor. Such insulation helps reduce heat loss to the ground in residences, cold storage units, warehouses and other commercial, institutional and industrial structures.

Rigid foam insulations, such as expanded polystyrene (eps), have been used successfully under concrete slabs for more than 40 years. Such insulation helps reduce heat loss to the ground in residences, cold storage units, warehouses and other commercial, institutional, cold rooms and industrial structures.

Putting the polyethylene above the foam minimizes the risk of iceberging, where if concrete gets under a corner of the foam during the pour it floats up, creating a thin spot in the concrete or even sticking out of the top surface. Contains 98% trapped air and.

Water resistant rigid board for under concrete slab insulation and slab support in traffic bearing applications. The most common types of under slab or concrete insulation include rigid foam insulations, such as expanded polystyrene (eps), extruded polystyrene (xps) and radiant insulation, such as prodex.

For Installation On Concrete Foundations And Under Floor Slabs, The Rigid Foam Insulation You Choose Can Make A Difference Of Tens Of Thousands Of Dollars On A Project.2 inches of foam under a slab. Additional insulation is applied along the edges of the slab ,. One solution would have been installing rigid insulation under the slab, turning it up on the perimeter (to form a giant pan), and then casting the concrete slab inside the pan.

Such Insulation Helps Reduce Heat Loss To The Ground In Residences, Cold Storage Units, Warehouses And Other Commercial, Institutional And Industrial Structures.Rigid foam under a concrete slab is a complex but important topic to dig into, especially when building codes come into play. Finally, some contractors in cold climates began installing a continuous horizontal layer of rigid foam insulation under their concrete slabs. Benefits of foam insulation under concrete slab.

The Most Common Types Of Under Slab Or Concrete Insulation Include Rigid Foam Insulations, Such As Expanded Polystyrene (Eps), Extruded Polystyrene (Xps) And Radiant Insulation, Such As Prodex.Xps and eps rigid insulation is used under concrete slabs. Say you use an average (and relatively inexpensive) rating of 40 psi, then the insulation will support: Using foam insulation under a slab drastically lowers your energy bill, complies with modern codes, and protects the life of the slab.

Water Resistant Rigid Board For Under Concrete Slab Insulation And Slab Support In Traffic Bearing Applications.Getting the sandwich layers in the right order Putting the polyethylene above the foam minimizes the risk of iceberging, where if concrete gets under a corner of the foam during the pour it floats up, creating a thin spot in the concrete or even sticking out of the top surface. Rigid insulation concrete products like foam sheeting are easily broken and must be used with an extra vapor barrier, plus standard foam or polystyrene concrete insulation does not stop radiant heat.

Let's Look At Each Type Of Insulation In More Detail.Ecofoil under slab insulation is superior to traditional, outdated forms of concrete floor insulation such as polystyrene or foam sheets. Rigid foam insulations, such as expanded polystyrene (eps), have been used successfully under concrete slabs for more than 40 years. From the building science web site:a sheet polyethylene vapor barrier should be located over the rigid insulation and in direct contact with the concrete slab.

Komentar

Posting Komentar